Product

Sustainable development goals

These 17 sustainable development goals, linked to 169 targets, form the basis of our sustainability strategy. These goals, which are one and indivisible, reflect the three dimensions of sustainable development: the economic, social and ecological dimensions. The goals can be subdivided into five main themes: humankind, planet, prosperity, peace and partnership.

Engineered to last

Our mission is imagineering. Engineering with limitless imagination, yet always keeping the idea of reusability and ecology in mind. Back in the days, most exhibition stands were made from wood, good for one single use and easy to throw away after the show. To break this polluting cycle, we’ve designed a modular exhibit building system made from aluminum, that can be endlessly reused. Across our products, including profiles and frames, our modular LED tiles, furnishings, and even our packaging solutions, we aim to improve.

Tried and tested

With research and development forming the core of our company for more than 20 years, we build intelligent products with a clean design, while continuously striving for new technologies. Every solution we generate is subjected to various sustainability tests from the prototyping phase through the final engineered product to ensure the highest adherence possible to sustainability standards.

Endlessly recyclable

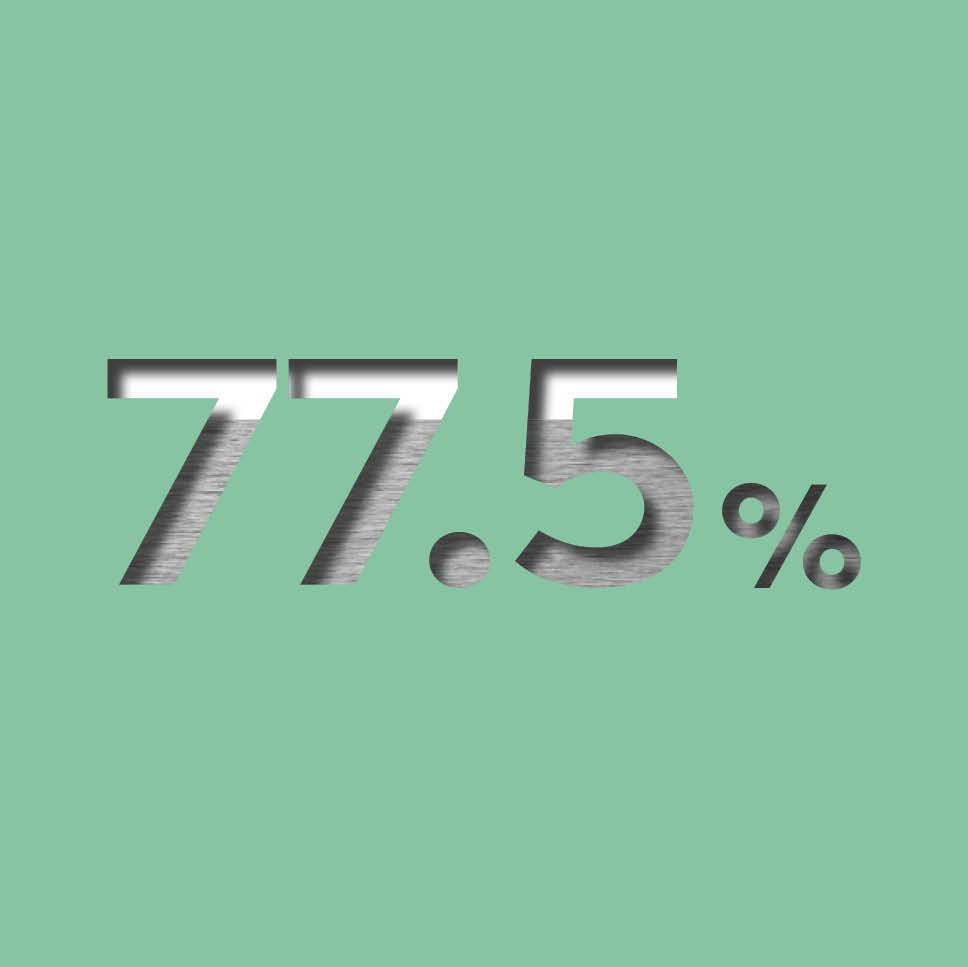

We opt for a 100% reusable end product and for sustainable materials. Did you know aluminum is the most commonly found metal on our planet? It’s strong, yet light. It has a long life cycle and is fully renewable. This results in greener and smarter solutions for everyone. The recycling process only requires about 5% of the energy compared to the production of primary aluminum. We can say that at least 77.5% of our frames are produced from recycled aluminum.

Standards for production

We elect to press our frames using a patented process invented by Aluvision. We also take the extra step to anodize our aluminum profiles. Anodization creates a “barrier”, leaving the surface scratch and dirt resistant, and keeping the oils excreted from raw aluminum at bay. Not only does the increase durability and longevity of use; it ensures less byproduct waste in the use of gloves, soaps, and water in handling our product. Anodization has no influence on the recycling process of aluminum.

The bigger picture

As we innovate modular systems for exhibition design, finding balance between elegance, efficiency, profitability, and sustainability is paramount. That is why, next to using less material, our sustainable strategy also translates to smart designs. Our product, and how we package it, allows for smaller storage spaces and fewer trucks to transport our goods. Thanks to our two production facilities in Kortrijk (BE) and Atlanta (USA), and a parts depot in Las Vegas (USA), we avoid unnecessary transportation and bring worldwide service and delivery to our customers. What’s more, our Aluvision Connect Program program brings together all our partners in an inclusive effort of sustainability and the sharing of knowledge and resources.